Just how rare are rare earth elements? It depends on their price.

There are 17 REEs, with funny names like gadolinium and dysprosium—and all of them are metals.

Their special magnetic, thermal, and corrosion-resistant properties have led engineers to use them in our most familiar electronics.

The rarest ones are still 200 times more plentiful than gold. And the most common are as abundant in the Earth’s crust as nickel, zinc, or lead.

The challenge is that they’re rarely concentrated enough to mine. And when they are, it takes heavy processing with heat and acid, which produces salty, radioactive wastewater.

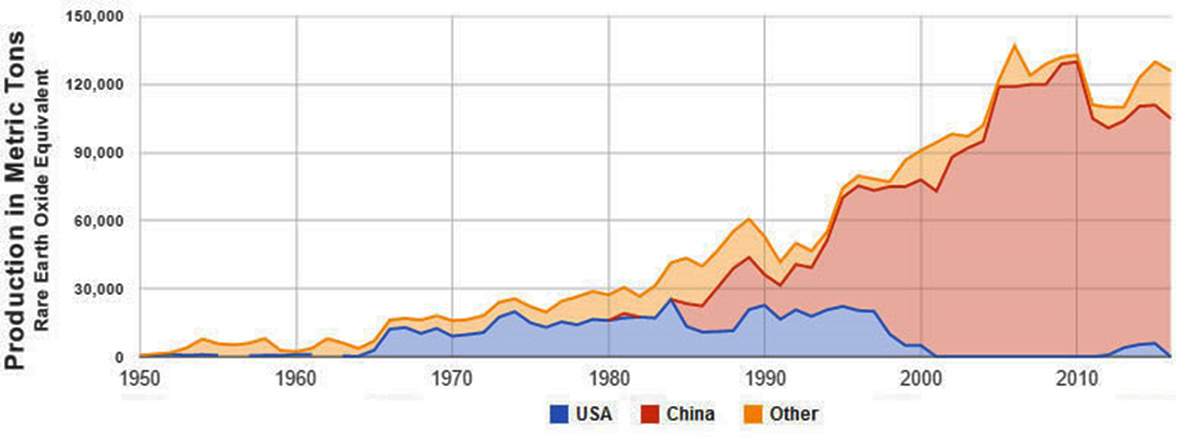

California was the largest producer of rare earth elements—till China entered the market.

Lower labor costs and looser environmental regulations allowed China to produce such a large supply so cheaply that U.S. mines closed.

With rare earth elements common and cheap, engineers used them in thousands of products.

But once China dominated the market, they began to raise prices and limit supply, to apply political pressure to electronics makers, like Japan.

But this backfired: Higher prices encouraged mines in other countries to reopen and discouraged engineers from using rare earth elements in new designs.

Which goes to show that rare earth elements, like all resources, are subject to the laws of economics.

Supply often depends on how much we’re willing to pay. If the price climbs beyond that, we start looking for alternatives.

Background

Synopsis: Rare earth elements (REEs) are critical and strategic minerals that governments monitor because they are crucial for high-tech products.

- REEs are elements 57 to 71 on the periodic table, plus scandium and yttrium.

- REEs are used in small quantities, but they improve performance; their key characteristics are magnetism, temperature resistance, and corrosion resistance.

- REEs are required for military state-of-the-art guidance systems; laser, radar, and sonar technologies; and electronic displays.

- You probably depend on them in your smartphone, tablet, computer hard drive, flat-screen monitor and television, anti-lock brakes, airbags, electric or hybrid vehicles, and even sunglasses.

- Geologists joke that REEs “aren’t really rare, they’re just playing hard to get.”

- REEs are abundant in Earth’s mantle but only concentrate near the surface in igneous intrusions and their late-stage veins as fluorocarbonates (bastnaesite) and phosphates (monazite and xenotime). They may also concentrate in nearby beach sands.

- Heavy processing with heat and/or acids is required to separate and refine ore into individual REEs from these igneous minerals.

- Mountain Pass, California, hosts one of the world’s richest REE deposits as bastnaesite in an igneous Precambrian carbonatite deposit.

- As REE-rich igneous intrusions break down over millions of years they leave behind clay deposits. REEs are physically adsorbed onto these laterites as the rock weathers away, and this is particularly effective in sub-tropical climates.

- Ion-adsorption clays are lower grade ore, but are much easier to mine and process—they make up about a third of China’s total REE production.

- REE production is probably more about chemical engineering than mining.

- Dangerous byproducts of processing such as extremely salty, radioactive wastewater can create environmental issues.

- In the 1970s, the U.S. led the world in REE production, principally used to make color TVs.

- In the early 1970s, the Nixon administration hosted Chinese scientists as part of normalizing relations between the two countries. With rich deposits of REEs in China, REE processing techniques were some of the technologies shared.

- China developed their REE resources and improved processing technology. With cheap labor and less-stringent environmental standards, they ramped up production and dropped prices, causing U.S. mines to close by 2002 because they could not make a profit.

- In the 1990s, the Chinese government began to control the REE market worldwide.

- As China’s market share increased and higher technology required REEs, the U.S. government became concerned about economic and strategic disruptions.

- In 2010, U.S. concerns were realized: China appeared to have developed a new economic super weapon—the REE embargo.

- In 2010, Chinese export restrictions drove prices up.

- In September 2010, Japan detained the captain of a Chinese fishing trawler in a disputed maritime area along their borders.

- The Chinese government announced they would stop all REE exports to Japan, necessary for many electronic and automotive exports; Japan immediately released the fisherman.

- Although monopolistic control of a key resource appeared to provide China with new power over its trade partners, the super-weapon embargo tool ultimately turned out to be less effective than expected.

- Rampant smuggling and large inventories—some caused by initial panic buying—buffered the need for the small amounts required for consumer products.

- Many uses of REEs originally developed because they had been very inexpensive; technological adjustments decreased demand when REEs became more expensive.

- Expectation of high prices encouraged exploration and development of new mines around the world, creating competition for Chinese REEs.