It may surprise you to know that one of the most important minerals in history has been … potash.

Many centuries ago, humans discovered that if you took a pot, put in wood ash, boiled it then strained out the residue, you’d get potash—which had two very special qualities.

First, when mixed into soil it made an excellent fertilizer for crops. Second, when mixed with sulfur and charcoal it made gunpowder.

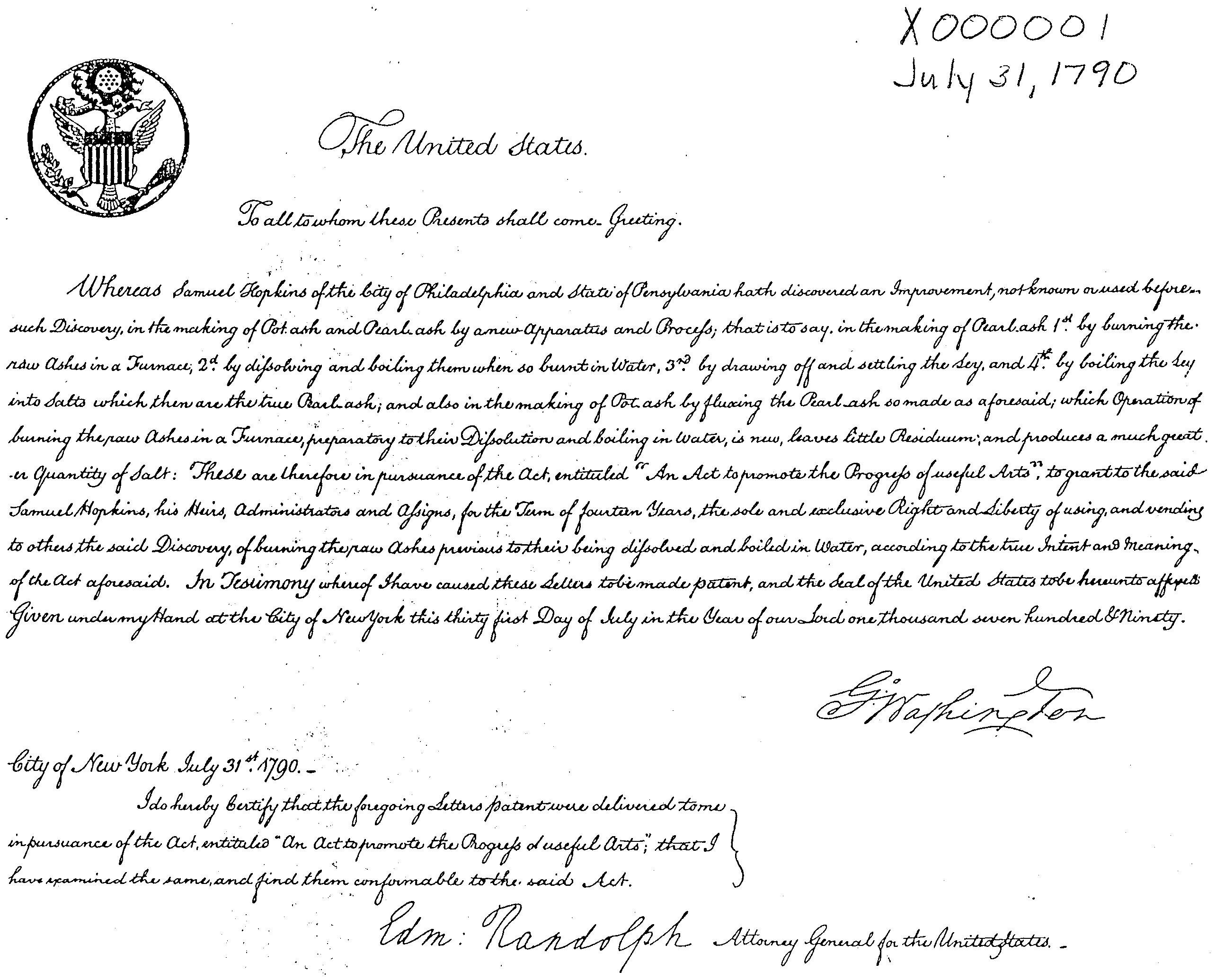

Potash was so valuable that the very first U.S. patent, signed by George Washington himself, was for a process to make more potent potash.

As the country grew, and more fertilizer and gunpowder were needed, whole forests were burned to make potash.

Trying to understand its properties, chemists figured out that potash contains several compounds of a metal they called potassium.

But there was still no other commercial supply…until the Germans discovered—and began to mine and export—potassium salts, like sylvite. And quickly dominated the market.

Shortly before World War I, they cut off potassium to the U.S. and other countries, who went looking for their own mines.

Today, Canada produces nearly a third of the world’s potassium. The U.S. imports most of ours from them. And most of that goes into fertilizer to grow crops to feed the American people.

In this way, potassium remains an important and strategic commodity.

Background

Synopsis: Potash has been essential to humans for millennia in the manufacturing of soap, glass, ceramics and gunpowder. In the mid 1900s, farmers figured out that it also helped their crops grow larger and more drought resistant, and, today, it is an essential ingredient of fertilizer. Potash is a term used for several water-soluble potassium compounds that were originally derived by burning wood, boiling the ashes, then evaporating the liquid in the pot to precipitate “pot ash.” Potash is also mined from evaporitic salt deposits, with Canada, Russia and Belarus as the top producers. Today, more than half the world’s population depends upon fertilizer for their food supply, and there is no artificial substitute for potassium in fertilizer.

- The earliest record of the use of potash comes from the Sumerian civilization around 4,500 years ago.

- Sumerians had factories where wool was spun into yarn, dyed and woven into textiles.

- Natural wool fleece shorn from sheep is saturated with lanolin, a greasy fat that helps the coat shed water and prevents it from matting. Lanolin must be removed from wool before it can be dyed.

- Sumerian cuneiform tablets from Girsu, an ancient Sumerian city in what is now southern Iraq, record the use of potash to clean wool around 4,500 years ago.

- It is thought that early weavers learned that washing wool in water with wood ashes created a soapy foam, improving the speed and effectiveness of cleaning.

- The animal fat in the wool’s lanolin combines with potassium in the ashy water through a process called saponification to create soap.

- The first documentation of using soap for hand washing and health purposes occurred about 1,000 years later.

- It wasn’t long afterward that humans learned to create soap for use in other applications using a simple process.

- Burn broadleaf hardwood to create ashes.

- Boil the ashes in water.

- Strain the liquid and allow it to dry in the sun.

- The white precipitate left in the pot became known as “pot ash.”

- When pot ash is combined with animal fats, it undergoes saponification, producing the cleaning foam we know as soap.

- Around 450 BC, glass containing potash was used to decorate a sword in the Yue region of southern China.

- Potash reduces the melting point of glass and makes it less brittle.

- While searching for a life-extending elixir around 800 AD, the Chinese learned that combining potash with nitrates produces potassium nitrate, or saltpeter, a key ingredient in fireworks (ED-115).

- A couple of centuries later, the Chinese figured out they could also use saltpeter, charcoal and sulfur in bombs and rockets, enhancing their wartime capabilities.

- The first United States patent, signed by President George Washington on July 31, 1790, illustrates the importance of potash to the new country.

- It documented a new process to enhance potash production by burning the hardwood ashes a second time to increase the concentration of potash in the liquid prior to precipitation.

- Pioneers broke even on labor for clearing their land by selling wood or wood ashes for potash to produce gunpowder. The practice was so common that many North American forests were decimated.

- Potash was the first industrial mineral produced in the American colonies.

- Potash is a mixture of water-soluble potassium compounds, including potassium carbonate, potassium hydroxide and potassium chloride.

- In 1807, a chemist named William Davy used electrolysis to show that potassium was distinct from sodium; the two alkali metals share many characteristics and often occur together in nature.

- Potassium is abundant but never occurs in its pure state in nature because it is highly reactive. Like the other alkali metals, it has just one electron in its outer orbital, so it energetically combines with other elements.

- The soft silver metal explodes in water, so pure potassium must be stored in oil.

- It has an atomic number of 19 and is represented by the symbol K for the Latin kalium, which means alkali.

- In 1861, potassium salts in mineral form, sylvite, were discovered and mined in Germany.

- This new abundant source gave Germany a near global monopoly in potassium.

- Looking for additional ways to use potash, the Germans tried it on farmers’ fields and discovered it increased yields.

- Potassium improves water retention and the movement of sugars in plants, increasing both yield and nutrient value of food crops, as well as boosting resistance to both drought and disease. It improves flavor, color and texture of food.

- Potash (K) quickly became essential around the world in fertilizers, along with phosphorous (P) and nitrogen (N). Fertilizer bags show N-P-K proportions.

- Potassium must be applied annually to crops and has no artificial substitutes.

- In 1910, four years before World War I began, Germany suddenly cut off potash exports.

- Governments became concerned because crop yields sufficient to feed their growing populations depended on fertilizer.

- This wartime strategy resulted in global exploration for sources of potassium that could be mined to replace the German exports.

- Sylvite, or potassium chloride (KCl), is known as muriate of potash and is formed in evaporitic basins as lakes or inland seas dry out and is often interbedded with halite (NaCl or table salt).

- In the United States, potash deposits of various geological ages were discovered:

- The first American mines were established in 1931 in the Permian Basin (Permian Castile Formations) near Carlsbad, New Mexico.

- Around the periphery of the Michigan Basin (Silurian Salina Formation).

- In the Paradox Basin (Paradox member of the Pennsylvanian Hermosa Formation) near Moab, Utah.

- In Pleistocene deposits of Searles Lake in southeastern California’s Mojave Desert.

- Potash is also collected from Utah’s Great Salt Lake.

- Potash deposits in Arizona, Nevada and North Dakota could be mined in the future.

- Mines were established in locations where the potash ore was buried deep underground until 1963 when a mine near Moab, Utah, exploded as miners encountered a pocket of natural gas, killing eighteen.

- Salt deposits are often associated with trapped pockets of hydrocarbons because the nonporous evaporites trap migrating oil and gas that may form as ancient organic-rich lake sediments are buried.

- In the United States, potash deposits of various geological ages were discovered:

- After the accident in Utah, Canadian miners in Saskatchewan discovered that the water soluble KCl could be more safely extracted at lower cost by pumping heated water into mine caverns to dissolve the ore and then producing the brine to the surface for evaporation in ponds.

- Today most deep potash mines (>3,600 ft or >1,100 m) use this process to produce potash brine.

- Evaporation takes around 300 days, so multiple ponds are filled through the year.

- Ponds are dyed blue by the addition of water-soluble copper sulfate that prevents algae growth and absorbs the sun’s heat more effectively to speed evaporation.

- When dry, the potash crystals are loaded into large trucks and further purified before distribution.

- The United States produces just over 1% of global potash production, using 85% of it for fertilizer production and 15% for the chemical industry.

- Today, Canada’s province of Saskatchewan produces nearly 29% of global potash production, and the United States imports about 80% of its potash from Canada each year.

- Russia and Belarus together produce about 14% of the world’s supply, followed by China, Germany and Israel.

- China, the United States, Brazil and India are the top consumers of potash.

- Potassium improves production of half the crops that feed the world’s population. It is essential for human health, but it may be strongly impacted by global politics.

- About 95% of the potash mined each year is used to fertilize about half of the world’s crops, feeding the global population.

- Potassium is an electrolyte, conducting electrical signals in the body that maintain blood pressure and enable muscles to contract.

- Despite diversification of production since export shortages of 1910, today’s global tensions (Belarus, Russia) still influence the distribution of potash today.