Credit: Liliane Tardio-Brise, via Wikimedia Commons

It would be hard to imagine a world without paper.

The Egyptians invented it three thousand years ago, using rushes that grew along the Nile River.

A thousand years later, the Chinese ground up mulberry bark and cotton to make paper for the emperor.

In another thousand years, the Moors used linen and hemp. They brought paper to Spain, where it spread to the rest of Europe.

It wasn’t until Gutenberg invented the printing press in 1450 that demand rose. But paper was still made one sheet at a time until 1800.

Then, machines were invented in France and Germany that used wood fiber to make paper on long continuous rolls. This technology made paper plentiful and cheap, and its use expanded.

Toilet paper, thankfully, was introduced around 1900. Paper towels around 1930. Disposable diapers around 1950.

Today, paper is made from fast-growing softwoods like pine and eucalyptus, which are ground and mixed with recycled paper.

About 65% of paper products in America today are recycled, but makers are looking to further reduce wood use. Some are now making paper exclusively from crop waste.

In today’s digital age, you’d think paper demand would have fallen. But its declining use in newspapers and magazines has been offset by packaging and shipping boxes.

Paper’s come a long way, while staying essentially the same—from the shores of the Nile to the box on your doorstep from Amazon.

Background

Synopsis: Imagine a day without paper—from holiday cards, boxes and wrapping paper to books, diapers, toilet paper and currency. Paper comes from plant fibers, which are a renewable natural resource. Early paper was made of a variety of plant fibers pressed into flat sheets, but industrialized paper shifted its source of plant fiber exclusively to tree pulp, consuming our forest resources. Recycled paper pulp has increased in recent years but must be mixed with virgin wood pulp. Encouraging new sustainable practices has come full circle as commercial paper companies now work with wheat farmers to use wheat waste to produce tree-free paper.

- Paper is all around us.

- Before the advent of the internet, most communication occurred in printed form on paper using books, newspapers, magazines, cards and letters.

- The consumption of paper has not dropped off since communication became digital, as increases in packaging; convenience products, like diapers, napkins and paper towels; toilet paper and even building materials have filled the gap.

Credit: Metropolitan Museum of Art, via Wikimedia Commons

- Paper is simply a flat mat of compressed and dried plant fiber. Invented more than three thousand years ago in Egypt, paper was made a single sheet at a time until 1798.

- Around three millennia ago, Egyptians wrote on papyrus made from rushes that grew on the banks of the Nile River.

- The first record of papermaking from tree pulp comes from the Han dynasty in around 105 BC when mulberry bark, fishnets, rags and hemp waste were pulverized together to make a sheet of paper for the Chinese emperor. This method gradually spread throughout Asia.

- The Moors developed hemp and linen paper around 1100 AD, passing it from North Africa and Spain to the rest of Europe.

- About one thousand years ago, the first paper currency was developed in China during the Song dynasty.

- Jiaozi were banknotes printed in Sichuan by merchants.

- Today paper currency is made from special blends of cotton and linen fiber for durability and to help prevent counterfeiting.

- In the 1450s, Johannes Gutenberg invented the printing press in Germany, greatly increasing the demand for paper.

- He produced 180 copies of the famous Gutenberg Bible.

- All paper was made one sheet at a time until the late 1790s when Nicholas Robert invented the first papermaking machine in France.

- The English Fourdrinier brothers and others improved upon the technology in the early 1800s.

- As paper demand continued to increase, methods for processing tree pulp were developed in Germany that led to the dominance of wood pulp as the principal source of paper pulp.

- The groundwood mechanical grinding method of making wood pulp became popular in the 1840s, producing newsprint type paper.

- In 1883, a chemical process known as the kraft (strong) process was developed. Kraft paper bags are still used in grocery stores today.

- American company Scott Paper produced the first toilet paper roll in 1890, improving it for use in public toilets by 1907.

- The first paper towels were also produced and sold by Scott Paper in 1931.

- The first mass-produced disposable paper diapers were produced in 1948 by Johnson & Johnson.

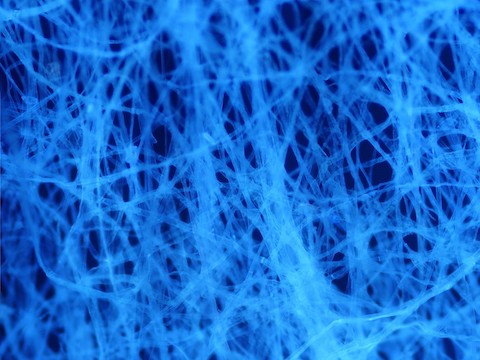

Credit: Egmason, via Wikimedia Commons

- Paper is held together by the microscopic roughness of plant fibers.

- Paper can be made from almost any fiber, including wood, cotton, hemp, flax, grass, straw, sugar cane, bamboo and rice.

- Paper is made in a similar way to the cloth we know as felt, but paper uses plant fiber instead of animal fiber (like wool).

- At a fine scale, plant fibers are crooked and hook together when a slurry of pulp is compressed, fusing to form strong yet flexible mats when dry.

- The length of the fibers from the plant determines the characteristics of the resulting paper.

- Longer fibers from softer trees like conifers produce paper with more strength.

- Shorter fibers from hardwoods produce a finer writing and printing surface.

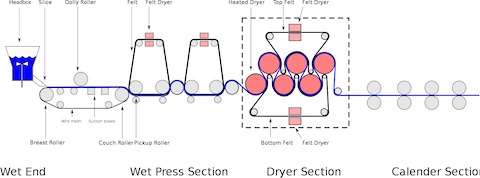

Credit: Richard Wheeler (Zephyris), via Wikimedia Commons

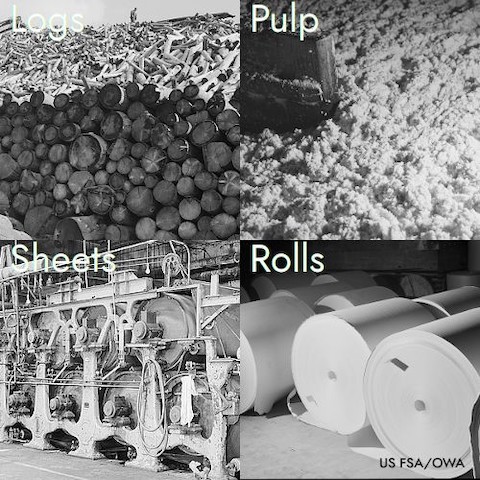

- Today, industrial paper is sourced from pulpwood logs and sawmill waste blended with recycled paper.

- Pulpwood trees are fast growing crops like evergreens and eucalypts that are farmed specifically to make paper.

- Once trees are harvested, they are transported to paper mills where their bark is removed, and they are shredded into small fingernail-sized chips.

- Some batches may be mechanically processed to make lower quality paper like newsprint, but most are cooked with chemicals and steam under pressure until they become a dilute suspension of wood fibers in water.

- The pulp is cleaned and sprayed on a moving screen where the water drains away, leaving a wet mat of fibers that is dried and run through heated rollers to flatten it.

- Modern paper machines can make a single sheet of paper up to 26 ft (8.8 m) wide and 40 mi (64 km) long every hour, resulting in giant rolls of paper that can be cut to size as needed.

- Colorful, smooth magazine pages get their smooth finish from the addition of china clay.

Credit: Historic photos by Jack Delano and others, U.S. Farm Security Administration/Office of War Information, courtesy of US Library of Congress.

- Paper making can be inefficient and wasteful of our forest resources.

- Most paper mills use only about 45% of a tree through chemical processing, separating out the white cellulose and burning the rest to produce energy. Some leading brand toilet paper production uses 100% virgin forest pulp.

- Some companies have turned to more efficient mechanical processes to make high-yield paper that uses 90% of the tree by using its lignin, normally a waste product.

- About 65% of paper products are recycled in the U.S. each year, but each time recycled paper runs through the process its fibers get shorter until they are too short to hold together. Typically, recycled papers are a mix of old and new fibers to ensure greater strength.

Credit: Ian Poellet, via Wikimedia Commons

- In 2013, one company came up with a different approach that harkens back to ancient papermaking methods.

- Columbia Pulp approached Washington State wheat farmers with a proposition to buy their wheat waste to turn it into pulp for papermaking. Wheat waste is the straw that remains in the fields after harvest.

- Disposal of the waste formerly cost the farmers, but now they can sell it to the paper mill, increasing revenues from their wheat crops.

- With wheat crop waste offsetting forest harvesting, undisturbed forests of Douglas fir, western hemlock and sitka spruce can be left in the ground as highly efficient carbon sinks (cultivated forests absorb less carbon than established forests).

- Two-thirds of wheat straw is made of cellulose that can be used in paper. Scientists from the University of Washington figured out how to process it using a new method called the phoenix process. The remaining one-third of the wheat straw waste is processed to make biopolymers for use in things like fertilizers and deicing agents.

- In 2019, Columbia Pulp became the first tree-free pulp facility in the United States to produce paper without felling a single tree while consuming agricultural waste. The wheat farmers were so enthusiastic about the long-term opportunity, they picked up shovels and helped to build the plant.

- If you are curious about what wheat waste-based products might feel like, visit a store and have a look at a cardboard six-pack of Corona Beer. Anheuser-Busch has already formed a partnership to use the sustainable fiber from the phoenix process.

Credit: Phase.change, via Wikimedia Commons

- It is very easy to make your own handmade paper at home by recycling used paper.

- Start by tearing up paper from your recycling bin and putting it into a blender with a lot of water (glossy paper won’t work).

- After blending it up into a soupy slurry, pour the mixture through a framed screen, adding dried flowers or other interesting items if you wish.

- Let it dry and peel it off the screen.

- Iron it on low setting to make it flat.

- Then frame it or fold it and send it to a friend as a card!